F22/F17/F14/F11 Structural Frame LVL Board with a Bond, H2s Treated, E0

Structural LVL Description: A high performance more sustainable alternative to lumber, LVL beams, headers and columns ar;

Basic Info.

| Model NO. | HC Flexframe |

| Formaldehyde Emission Standards | E0 |

| Specifications | 35mm, 45mm, 63mm, 65mm, 77mm |

| Place of Origins | China |

| Grade | Excellent Grade |

| Usage | Outdoor |

| Transport Package | Exported Seaworthy Package |

| Specification | customized |

| Trademark | HONGCHENG |

| Origin | Shandong China |

| HS Code | 4412330090 |

| Production Capacity | 5000 Cbm \Montth |

Product Description

Structural LVL Description:A high performance more sustainable alternative to lumber, LVL beams, headers and columns are used in structural applications to carry heavy loads with minimum weight. Murphy structural LVL products are manufactured in a controlled environment resulting in straighter, stronger and more uniform product compared to milled lumber, creating a more stable and reliable product than dimensional lumber because it doesn't twist and warp or shrink over time.| Materials | Larch pine/Eur Fur/Radiata pine |

| Grade | F22/F17/F14/F11/F8 |

| Glue | Dynea Phenolic , super E0, A-bond |

| Popular sizes(Length can be up to 12000mm), or as be required | 90x35mm |

| 140x35mm | |

| 170x35mm | |

| 190x35mm | |

| 240x35mm | |

| 90x45mm | |

| 120x45mm | |

| 140x45mm | |

| 150x45mm | |

| 170x45mm | |

| 190x45mm | |

| 200x45mm | |

| 240x45mm | |

| 290x45mm | |

| 300x45mm | |

| 360x45mm | |

| 400x45mm | |

| 90x58mm | |

| 130x58mm | |

| 150x58mm | |

| 170x58mm | |

| 200x58mm | |

| 240x58mm | |

| 300x58mm | |

| 360x58mm | |

| 400x58mm | |

| 450x58mm | |

| 300x75mm | |

| 400x75mm | |

| 525x75mm | |

| Density | 550-780kg/CBM |

| Loading | 35-47CBM/40'GP |

Private label provider

Custom stamping

Custom packaging

Literature support

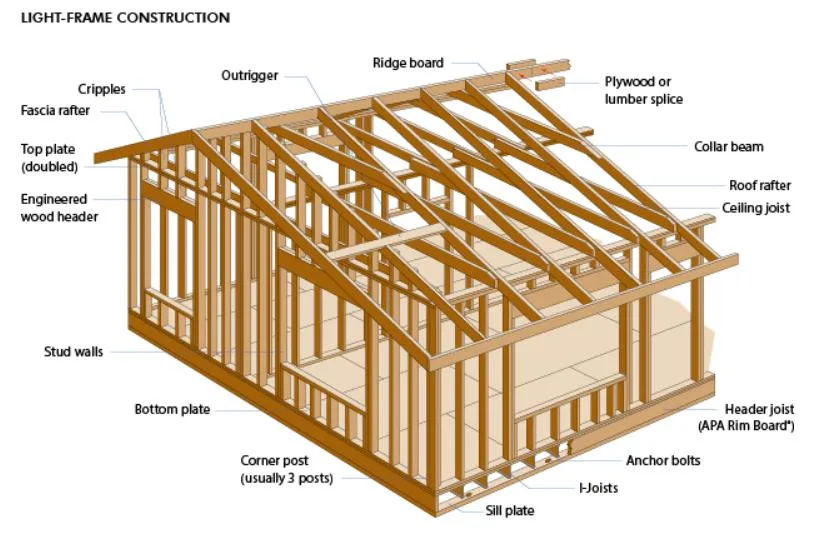

Usage as pictures showing:

Structural LVL Advantage:

- High Strength

- Dimensional stability

- Guaranteed technical date

- Corrosion resistance

- Easy length identification on site-ends are colour coded by length

- Faster and easier to install-enhances productivity and reduces

- According client's require to produce

- True sourced from environmentally sustainable plantation timer

- Veneer are bonded together using a type"A"(marine) bond, which has proven performance for in excess of 50 years

- Quickly assembly due to the ready-to-use prefab panels and installation of high strength frames without heavy lifting equipment.

- Light weight of structures results in less loads on soils and gives way to the usage of economical foundations.

- Usage of timber frames and modern insulation materials allows to construct 'breathing' houses, being warm during winter time and cool in summer.

- Houses have practically no shrinkage

Structural LVL Applications:

Partition walls

Trussing system(ridge beams, ceiling rafters, trusses)

Ceilings

Floor supports

Concrete forming

Timber frame construction

Structural LVL Construction Overview:

Laminated Veneer Lumber(LVL) is used in a variety of applications including beams, joists,trusses, frames, roof, floor and wall elements, components for the joinery industry(doors, stairs, windows) and vehicle industry, concrete formwork and scalffold boards.

Benefits of Form LVL:

- Enhanced durability and safety(OHSA/ANSI/BS/EN)

- Unrivalled structural rigidity, stability and strength

- Proven to last at least twice as long as solid wood equivalents

- 10% lighter than solid wood equivalents

- No metal end band required

- No on-going maintenance or remedial repairs required

- Excellent electrical insulation properties

- Excellent anti-corrosive and chemical properties

- Inherent strength properties of structural LVL mean that it can be cross-cut to exact lengths

with Benchmark Certification

You may also like

Send inquiry

Send now